Описание

Страна : Франция

Год : 1926

(проект)

Flight, December 1926

The Paris Aero Show 1926

S.E.C.M.

<...>

The S.E.C.M. 150T is a cantilever monoplane, with one central engine in the nose of the fuselage and two wing engines. The two latter are accessible during flight, it being possible for the engineers to get to them through the thick wing. The cabin has accommodation for 14 passengers, and the power reserve is such that the machine will fly on any two of its three engines. With one engine it loses height very slowly. Following is a specification of the 150 T.: Span, 23-9 m.; length, 18-0 m.; wing area, 100 sq. m.; weight equipped, 4,030 kgs.; pay load, 1,680 kgs.; speed at ground level, 235 km./hr.; cruising speed, 190 km./hr.; range (in still air), 1,000 kms.

<...>

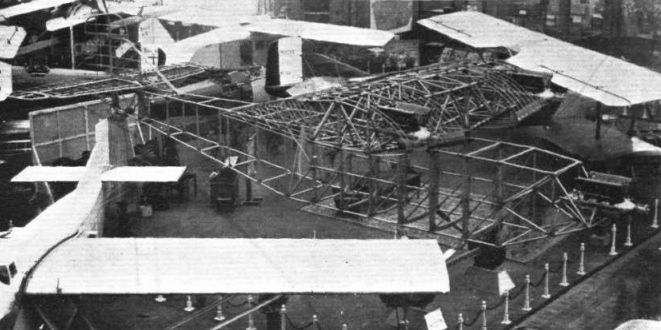

Of the second machine of this stand only the centre portion was shown, and this was exhibited in skeleton. It is to be a large commercial Vee-engined machine with three Hispano-Suiza engines. The fuselage is of typical S.E.C.M. tubular construction, in which the joints between struts and longerons are formed by wrapping metal sheet around the struts and longerons. This is a form of construction which the S.E.C.M. Company has developed to a high art, and which is certainly beautifully carried out, although it is a little difficult to see the necessity for this complication. The wing structure looks at first glance, somewhat like the well-known Junkers type with multiple tubular spars, but in reality it is quite different. To begin with, the main wing structure does not extend over the entire chord as is the case in the Junkers machines. It stops short aft at approximately mid-chord, while in front there is a separate leading edge formed of sheet metal. Moreover, when the structure is examined in detail, it is found that the top and bottom tubes of the spars occur one above the other, whereas in the Junkers construction a top tube occurs approximately above the midway point between the two lower tubes and vice versa. The method of joining all the various tubes together is also quite different from that used by Professor Junkers, and takes a form similar in general principle to that employed in the fuselage construction, with sheet metal wrapped around the joint. One such joint was exhibited on the stand, and showed a large number of tubes meeting at a point. It was impossible not to admire the skill and craftmanship which had enabled this joint to be made, but it is difficult to discover the necessity for going to such complicated methods of joining tubes together. From what will be gathered by inspecting the centre portion of this machine, the cantilever monoplane wing will have a very pronounced taper. The undercarriage appeared to be of the type in which the axle itself is rigidly mounted, but it was not possible to see whether or not shock-absorbing gear was incorporated inside the wheels. A photograph of a wheel, however, showed shock absorbers incorporated, although one doubts whether this type of wheel was actually used on the machine as exhibited.

- Flight, December 1926

The Paris Aero Show 1926

Фотографии

-

Flight 1926-12 / Flight

The S.E.C.M. 150T commercial machine, of which only the centre portion was exhibited (in skeleton). The wing construction is somewhat similar to the Junkers.

- Фотографии