General Aircraft ST-1, ST-2 и Monospar ST-3 - ST-12

Компания "General Aircraft Ltd", образованная в 1934 году, стала наследницей "Monospar Wing Co. Ltd". Приобретенное ценное имущество - экспериментальное крыло Monospar - определило курс новой фирмы в начальный период ее истории, который начался с постройки четырехместного General Aircraft Monospar ST-4. Ранее по заказу Министерства авиации экспериментальные крылья Monospar уже проходили испытания под обозначением ST-1, а затем ST-2 - они изготавливались на "Gloster Aircraft Company" и испытывались на принадлежащем министерству Fokker F.VIIb-3m.

Первым легким самолетом, специально спроектированным под новое крыло, стал трехместный Experimental Monospar ST-3, также построенный компанией "Gloster". Небольшой низкоплан имел полотняную обшивку и был оснащен двумя звездообразными моторами Salmson мощностью по 50 л. с. Интенсивные испытания Monospar ST-3 прошел успешно, после чего "General Aircraft Ltd" определили как производителя самолетов с новым крылом. Разработанное швейцарским инженером Х.Дж. Штейгером однолонжеронное крыло большого удлинения (Monospar) для повышения прочности имело проволочные растяжки, работавшие как торсионы.

<...>

Показать полностьюShow all

Flight, July 1931

AN INTERESTING EXPERIMENT

The little twin-engined light plane designed by the Mono-Spar Company, and built for them by the Gloster Aircraft Co., Ltd., has now been through its tests at Martlesham Heath. The machine was built to test out Mr. Stieger's monospar type of construction in actual flight, and the results have, generally speaking, confirmed Mr. Stieger's theories. The machine is described below. The actual production type will differ in certain details, but not in the general principle of the type of structure used. The experimental machine is a two-seater. The production model will be a four-seater.

UNIFORMITY of stress in the various parts of an aircraft structure is not readily attained. Mr. H. J. Pollard has pointed out, in his series of articles in THE AIRCRAFT ENGINEER (Monthly Technical Supplement to FLIGHT), that in the conventional biplane structure changes of loading occur which cannot, for manufacturing reasons, be followed by corresponding changes in the strength of the structure members. In a monoplane structure, and more particularly, perhaps, in a cantilever monoplane, the chances of proportioning the structure to the stresses throughout are a little better, but the cantilever monoplane is usually heavier than the biplane in spite of this, due to the smaller depth of structure. This applies particularly to the two-spar type of structure. Mr. Pollard has been working for some years on multi-spar wings, and some very interesting developments are likely at Filton.

In the meantime, Mr. H. J. Stieger, a young Swiss engineer, has conceived the idea of using a single spar, so built as to be strong enough to take all the bending and shear stresses, but braced in a special manner against torsional loads. It may be recollected that at the Olympia Aero Show a section of a wing built on this principle was exhibited. Since then work has been proceeding, and, as recorded in FLIGHT recently, a monospar wing for a three-engined Fokker monoplane is now nearing completion, and will be tested in flight shortly. About a year ago, the Mono-Spar Co., Ltd., decided to build a small aeroplane in order to test out the monospar principle in actual flight, and arrangements were made with the Gloster Aircraft Co., Ltd., to build the machine at their Brockworth works. For various reasons, the work has taken a considerable time, but the machine was finished some time ago, and has now been to Martlesham for tests. Consequently, a description and illustrations may now be published.

In the design of the machine, the monospar principle has been applied not only to the wing, but also, in effect, to the fuselage. That Mr. Stieger's claims for low structure weight are borne out seems to be indicated by the fact that the structure weight is a considerably lower percentage than is usually found in a machine of this type and size. Originally, the machine was intended to be fitted with two of the Redrup axial engines, but, as the experiments with these took longer than had been expected, two 50-h.p. Salmson engines of the 9AD type were fitted instead, and with these the machine flies very well indeed. It is not desired to give performance figures at present, as the machine will not go into production in its present form.

The experimental machine is a three-seater, with pilot and one passenger side by side, but slightly staggered, and a third seat behind them. Owing to the forward position of the pilot's seat and the absence of an engine in the nose of the fuselage, the view forward is exceptionally good. Large windows in the cabin give a good view outwards, although from the back seat the view is, as in most low-wing monoplanes, slightly interfered with.

The two Salmson engines are mounted on the wing, and direct gravity feed is provided by carrying the petrol in a tank in the fuselage nose, in front of the instrument board.

The wheels are provided with brakes, and a tail wheel is fitted in place of a tail skid. An experimental arrangement for coupling the brakes to the control column has been incorporated, so that, when the pilot pulls the stick back for a three-point landing, the brakes are operated. The interconnection can, however, be released when the brakes are operated by a centrally-placed lever in the orthodox manner.

As the machine under review is purely experimental, it is not thought necessary here to deal very much with its general features as an aircraft, which may be somewhat altered in the model to be placed on the market as soon as production gets going at the premises which have been temporarily acquired at Croydon aerodrome. It is, however, worth placing on record the fact that in the production of the experimental machine a considerable amount of wind tunnel work on thick wing roots has been done, and that, as a result, the difficulties of thick wing roots behind wing engines placed close to the fuselage have been overcome, and methods have been found for keeping the airflow smooth and retaining the controllability down to large angles of incidence.

Structural Features

The main reason for producing the monospar machine was, as already stated, to try out in flight the Stieger system of single-spar construction, and, as this will be retained in the production model, although with minor modifications, some notes on it here may be of interest.

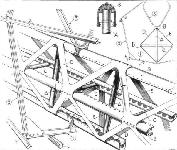

It will probably be recollected from previous references to the Stieger monospar system that this consists of a single main spar, strong in bending, but braced against torsion by what may best be described as "spiral" bracing wires, these wires consisting of two sets, which may be imagined as running around the wing in opposite directions. Under the Mono-Spar Company's patents, the single spar may, of course, be of any suitable construction. In the machine with which we deal here, it is an I-beam of duralumin, built up of several members. The web itself is a plain duralumin plate, with triangular holes stamped out for lightness, leaving a series of lattice bars to act as braces between top and bottom flanges.

The spar flanges or booms are built up of strips, and may be said to consist of angle sections riveted to the web, with reinforcing cover plates added on the outside. The angle-sections are not, however, of the usual plain flat type, but are of curved shape, as shown in the sketch A on p. 668. A flange of this shape should be a good deal stronger in compression than one consisting of plain flat angle sections, as the members composing it help to brace each other. At the same time, the spar should not be an expensive one to manufacture, and, where local reinforcement is necessary, this can be provided by extra laminations on the outer faces of the spar. The spar web being, as already stated, perfectly flat, is stiffened here and there by vertical members of V-section, also shown in sketch A.

The "spiral" bracing of the wing takes the form of tie rods anchored at their ends to the apices of tubular king post ribs, and to plate fittings on the spar flanges, where the tie rods of a bay cross each other. This "spiral" bracing does not extend right out to the wing tips, but finishes on the spar just beyond the inner end of the aileron. From this point to the wing tip the bracing is taken over by the false spar carrying the aileron. This spar is placed at a pronounced angle with the main spar, which it meets at the wing tip, thus triangulating the structure.

The wing is in three pieces, of which the centre portion is built integral with the fuselage, and contains the engine mountings. The two outer wing portions are attached by three bolts each, two on the spar flanges and one on the forward king post. In the centre section the struts supporting the engine bearers are used as the king posts in the wing bracing system.

Wing ribs of orthodox type are employed, and resemble those used on "Gloster" machines for several years, with the fabric wired on to the ribs in the "Gloster" manner.

As already mentioned, the monospar system of construction has been applied to the fuselage also, although naturally in a modified form. The main structure member of the fuselage is a beam of relatively shallow depth, and reminds one, in principle if not in actual form, of the steel tube used in early Breguet machines. In the monospar machine, however, this beam is an open girder of duralumin, of square section, and "standing on a corner." The four corner booms of this beam are of built-up D-section, and are joined by an outer cover of duralumin sheet, stamped out to form lattices like the main wing spar web. This cover braces the fuselage beam, and consists in two halves, the free edges of which overlap on the top and bottom booms. This form of construction appears needlessly expensive, and one would have thought that a number of standardised short lattice bars would have been much cheaper to manufacture.

A hollow square-section tube like that just described would collapse inward under low load, and to prevent this the four booms are kept apart by tubular distance pieces running from corner boom to corner boom, vertical distance pieces alternating with horizontal ones.

The fuselage beam is placed at the bottom of the fuselage, and is anchored to the wing spar of the centre-section by a large tubular vee. The attachment is considerably complicated by the fact that the fuselage boom is "standing on a corner." Had it been lying flat on one of its sides, the attachment could have been made to the spar direct, much as is that in the Breguet "Tout Acier."

The fuselage shape proper is obtained by hoops of trough-section duralumin and fore- and aft-stringers of similar section. In the side view of the machine in skeleton no wiring is shown, but actually a certain amount of "spiral" wiring was added to the fuselage after the first test flight to get greater torsional strength. This wiring had the desired result, and the machine is now, we understand, thoroughly rigid and free from torsional and flutter troubles of any kind.

The slipstream from the two propellers, running as they do close to the fuselage and wing roots, caused a certain amount of trouble at first, but the designers have now succeeded in finding means for smoothing out the airflow, and the machine is reported to be remarkably pleasant to fly. In landing, it shows no tendency to "kite," but sits down without any trouble at all.

As previously mentioned, the Mono-Spar Company has secured temporary accommodation at Croydon, and here the work of building the production type will be begun. Later it is possible that a move will be made to another aerodrome in South London.

Показать полностьюShow all

Flight, October 1931

A MODERN AIRCRAFT

AN aircraft which breaks away from the Wright Bros.' lay-out, and which incorporates many really modern features, is the Monospar. This machine is at present being developed in a factory at Croydon Aerodrome by the General Aircraft Co., Ltd., and has been designed by Mr. Stieger. It was described in FLIGHT for July 10, and now that we have been able to try it out for ourselves, we are able to say more about it. We have always maintained that to sell aircraft to the average user, they must be as comfortable and as well fitted as the ordinary motor-car. Few aircraft fill these requirements, but the Monospar in its production form will certainly do so, and should, therefore, sell well.

The existing model was primarily built with the avowed intention of trying out the principles involved in manufacture, particularly the Monospar wing and fuselage, and not with the idea that it was the first of its type. In the first place, it is flying with somewhere about one-half of its designed horse-power, owing to the fact that the engines for which it was designed were not available when it was ready and comparisons cannot therefore, in fairness, be made with the production model which should be out shortly. A very good idea can be gained, however, as to what the new type will provide, and that it should cause quite a stir in aeronautical circles seems certain.

After flying a conventional aircraft with a single engine in front, it is a revelation to get into the Monospar and find an absolutely unobstructed view in all directions, the sense of relief and security which this gives the private owner will be a very strong selling point for this machine. On the ground one is at once struck with the sensibility of the whole lay-out, the brakes are operated in just the most handy manner, so that their use immediately becomes quite natural and these together with the two engines make it possible to manoeuvre the machine through the thickest of ground traffic unaided by anyone on the wings. This is a point which is rapidly becoming a problem of peculiar urgency, since at even a small flying meeting nowadays we are quite likely to have anything up to 50 aircraft present.

In the air the Monospar is equally comfortable. Even with the existing engines the present model can maintain its height on one engine and turn against that engine with ease, while the controls are positive and very effective in all directions. One point which will have to receive attention not only in the Monospar, but in all low-wing cabin monoplanes, is the reflection from the upper surface of the wing on the front windows of the cockpit. We imagine that the wing will have to be doped with a dark matt surface or something of a similar nature, for with an aluminium finish the windows become distinctly difficult to see through when the sun is anywhere abaft the beam.

The new model will be a full four-seater, fitted with two Pobjoy engines, and will be one of the fastest light aircraft in this country. If it maintains the extremely quick takeoff and the easy landing qualities of this first model, then it will certainly be one of the most desirable aircraft extant.

Показать полностьюShow all