Фотографии

-

This photograph of the first prototype of the Gripen, the JAS 39-1, taken at Linkoping on the evening prior to the official unveiling (on 26 April last) of this new multi-role fighter, reveals the aesthetically attractive lines that have been attained by the Saab design team. This aircraft is expected to be joined in the flight test programme during the latter part of next year by the JAS 39-2, with -3, -4 and -5 following at approximately six-monthly intervals. The first prototype will be primarily occupied with aerodynamic testing and exploration of the performance envelope, successive prototypes being devoted to avionics, weaponry trials, etc. Although the Gripen is optimised for the unique Swedish defence demands, which include the ability to operate from 875-yard (800-m ) strips of motorway, Saab-Scania believes that it will offer good export potential, particularly when the Growth II and III versions of the RM 12 become available for installation.

Самолёты на фотографии: SAAB Gripen / JAS-39A/C - Швеция - 1988

-

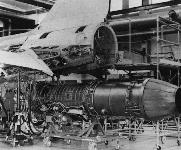

The RM 12, the first flight test example of which is seen here in process of installation in the JAS 39-1 Gripen, has been developed by Volvo Flygmotor in collaboration with General Electric from the latter company's F404-GE-400. Optimised for Gripen installation, the RM 12 offers a substantially improved performance over that of its progenitor, and successively more powerful versions are in prospect from the early through the mid-'nineties.

Самолёты на фотографии: SAAB Gripen / JAS-39A/C - Швеция - 1988

-

The first prototype Gripen is seen here during the unveiling ceremony which took place on 26 April last to coincide with the 50 th Anniversary of the creation of what is now the Saab Aircraft Division of Saab-Scania as the Svenska Aeroplan AB.

Самолёты на фотографии: SAAB Gripen / JAS-39A/C - Швеция - 1988

-

Самолёты на фотографии: SAAB Gripen / JAS-39A/C - Швеция - 1988

-

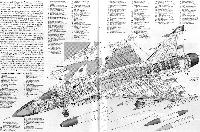

Saab JAS 39 Gripen

Самолёты на фотографии: SAAB Gripen / JAS-39A/C - Швеция - 1988

-

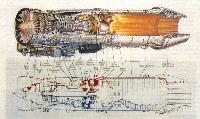

The schematic drawings above illustrate the principal features of the RM 12 engine for the Gripen. Volvo Flygmotor is responsible for final assembly and manufacture of between 30 and 35 percent (by value) of its component parts. These parts comprise: HPT rear shaft, LPT disk, LPT forward seal, LPT conical shaft, forward and rear plate cooling, HPT disk, seal rotation, spool stages 1-2, HPC front shaft, disk stage 3, front and rear compressor cases, LPT and HPT nozzle segments, air seal LPT nozzle, case LPT, support shroud HPT, afterburner mixer and case, combustion and afterburner liners, combustion case, fan disk stages 1 and 3. mounting ring, inner nozzle support, fan case, flame holder, primary flap and seal, and rear fan shaft. Volvo Flygmotor will have full responsibility for the RM 12 after completion of operational testing which is scheduled for the third quarter of 1990.

Самолёты на фотографии: SAAB Gripen / JAS-39A/C - Швеция - 1988

-

Самолёты на фотографии: SAAB Gripen / JAS-39A/C - Швеция - 1988

Статьи

- -

- Fighter A to Z

- In print

- Model enthusiast

- Talkback

- ??? - Magyar Air Cover

- ??? - Mr Mac's First Phantom: The Story of the McDonnell FH-1 /Warbirds/

- ??? - The Gripen ... an ambitious "Jack of all Trades"

- G.Jones - Miami Virtue

- P.Jackson - Royal Jordanian Air Force: Air Power at Three-continent Crossroads

- R.Braybrook - A World Gome Mad