Описание

Страна : Великобритания

Год : 1920

Летающая лодка (проект)

Flight, September 1920

THE AIR MINISTRY SEAPLANE (AMPHIBIAN) COMPETITION

The Beardmore W. B. IX

Quite extraordinary interest attaches to the machine entered by Wm. Beardmore and Co., on account of its unusual construction no less than because of its central engine arrangement with transmission drive to airscrews on the wings. The general arrangement of the machine will be understood by a reference to the accompanying scale drawing. The W. B IX, it will be seen, is a flying boat of the "Batboat" type. That is to say, its main hull is relatively short and does not carry the tail, which is supported on a separate structure of the open girder type. The main planes have a span of 107 ft., and the lower plane is of considerably smaller chord than the upper. The total wing area is 2,202 sq. ft., so that the machine is far from being a "Tabloid." The overall length is 61 ft., and the height is 20 ft. 6 ins. The wings, which have a straight centre section to which the end “sections" are set at a dihedral angle, are designed to fold, when the overall span is reduced to 51 ft. 6 ins. The size of hangar necessary for housing the machine is thus reduced to about 53 ft. wide by 62 ft. long by 23 ft. high. The weight of the machine empty is 9,520 lbs. and fully loaded 14,000 lbs., giving a wing loading of 6.35 lbs. per sq. ft. The power of the four Beardmore engines is 800 h.p., giving a power loading of 19.4 lbs. per h.p. The load carried is composed as follows:

Passengers - 10 at 160 lbs 1,600 lbs.

Luggage - 20 lbs. per passenger 200

Pilot 180

Engineer 180

Petrol 1,900

Oil 220

Water 200

Total 4,480 lbs.

As the machine has not yet been tested, actual performance figures are not available, but the following estimated performance data are of interest :-

Max. speed at ground level, 93 m.p.h. At 10,000 ft., 82 m.p.h. Landing speed, 46 m.p.h. Climb to 5,000 ft., 14 minutes. To 10,000 ft., 38 minutes. Range near ground level at full speed, 403 miles. Petrol consumption per hour, 58 gallons. Oil-consumption per hour, 4.2 gallons.

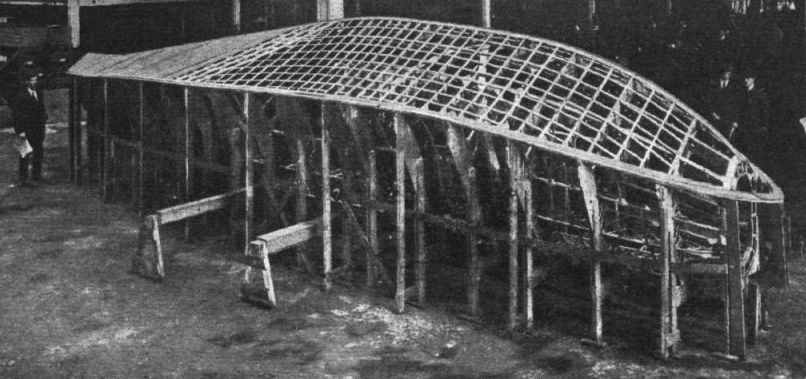

Hull Construction

Reference has already been made to the interesting construction of the boat hull of the W.B.IX. Instead of the usual wood longitudinals and transverse formers, this machine has 16 longitudinal Duralumin girders spaced around circular frame girders. Longitudinal as well as transverse girders are built up of top and bottom channels forming the flanges of the girders, braced by light airship type lattice bars. The transverse formers are spaced 2 ft. apart, and are fitted in as segments between longitudinal girders. One of the accompanying illustrations - a longitudinal and a transverse section of the hull - will help to give an idea of the general lay-out.

Such members as keelson and chines are of rock elm but the structure supporting the chines is a series of duralumin cantilever girders of similar general design to that of the main longitudinal and transverse girders. The outer covering of the hull is also of wood, consisting of two skins of mahogany, of which the inner skin is laid on diagonally, the outer one longitudinally. A layer of fabric is placed between the two skins and varnished and nailed in place, thus adding greatly to the strength and water-tightness of the hull The lower part of the hull is divided into six watertight compartments, so that in the case of one or more compartments being flooded there is still sufficient buoyancy to prevent the machine from sinking. From the bilge pump a pipe leads to each compartment.

Cabin Arrangements

The passengers' quarters are divided into two-compartments by the engine room. The front cabin, in the nose of the hull, seats two passengers comfortably and three without undue crowding. The cabin aft of the engine room is larger and seats four passengers comfortably. There is even room for a table, but it this is not required seating accommodation for six passengers can be provided. If necessary an extra passenger can be accommodated in the pilot's cabin, bringing the total passenger capacity up to 10.

As will be seen from the sectional view of the hull the pilot is placed m a separate cabin above the engine room. From here he has an excellent view through Triplex glass windows in the side. These windows can be raised and lowered so as to provide not only ventilation but also a free view during rainy or foggy weather. A door in the side of the pilot's cabin gives access to a walking-way on the lower plane, while the engine room below is reached via a trap-door in the floor and by means of an accommodation ladder.

The Engine Room

Perhaps the most interesting part of the hull is the engine room, in which are installed the four 200 h.p. Beardmore engines. Ample space is afforded in which to move about and attend to the engines during flight, and minor adjustments and repairs can be effected en route, as each engine is provided with a clutch and can be thrown out of gear while being inspected. The engines are arranged in pairs, one pair on the port side and one pair on the starboard side. In each pair the engines are placed with what is normally their propeller ends facing one another, but separated by a gear-box which takes its drive from each end through bevel wheels. Each engine has its clutch - of the multiple plate type, with 26 plates of steel and 26 of phosphor bronze. A flexible coupling is fitted between the clutch and the gear-box to allow of ease of alignment. Another feature which is rarely seen on aero engines nowadays is found on the Beardmore engines of this machine - in the shape of a substantial flywheel. The fitting of this allows of the engine being run free for purposes of testing, and also tends to reduce vibration in gearing and shafting.

From the primary gear-box in the hull a vertical - or more correctly speaking a diagonal - tubular shaft of special axle steel transmits the drive to a secondary gear-box placed between the wings and supported by vee interplane struts. This intermediate shaft is fitted, in the centre of its length, with a self-aligning, anti-whirling bearing, and has sliding universal couplings at each end. The whole shaft is enclosed in an oil-tight casing, and forced lubrication by pumps is employed throughout the transmission drives.

The propeller hubs in front of the secondary gear-boxes are of the full floating-type, i.e., the hubs run on steel extensions bolted to the nose of the gear-boxes and are driven by torsion shafts. These shafts run through the hollow nose pieces, and drive the hubs by means of dogs cut in the shafts and hubs.

The propeller thrust is taken by a ball thrust race at the rear end of the hub.

The propellers, which are placed close together, are of the four-bladed type, with brass tips to protect them against spray. This arrangement of the propellers close together should be of great advantage in case of engine failure. Not only is the "leverage" of each propeller small, but in case of one engine cutting out the other still continues to drive the propeller, although naturally at a reduced speed. Consequently the yawing moment caused by the failure of one engine should not be anything like as great as it is in the case of a machine with the engines on the wings, where not only is the distance between the two centres of thrust usually greater, but in case of one engine cutting out the thrust on that propeller disappears. Not only so, but there is a negative thrust on the airscrew, which adds further to the already considerable yawing moment. If, therefore, the transmission drive of the Beardmore W. B. IX proves satisfactory, the type should have much to recommend it.

Petrol System

There are in all seven petrol tanks on the machine. Over each engine is a gravity tank, supplied from the main tank by gravity feed. The main tank is placed aft of the pilot's seat, in the coaming behind the cabin, and a further two tanks are hung near the sides of the engine room itself. Petrol is pumped from these two latter tanks - which may really be regarded as reserve tanks - by Austin glandless pumps, driven from engines when required. Ample size piping is fitted, and all flexible connections are made with braided flex hose, no rubber joints being employed. The fuel is passed through a central distributor and is thoroughly filtered. Alternative supply piping is arranged to all engines in case of pipes or connections being damaged. The petrol tanks are of welded aluminium and the oil tanks of 24 gauge tinned steel.

The Undercarriage

The "amphibian" part of the landing gear is in the form of two large Palmer aero wheels mounted on a hinged vee-structure, which is folded by means of the hinged rear struts. The raising and/or lowering of the undercarriage is done from the engine room, and is in charge of the engineer. The shock-absorbing arrangement is in the form of rubber cord and "Oleo" gear, and stops are provided to limit the movement of the axle. The track of the undercarriage is wide - about 16 ft. - and should give good stability on land. The tail skid acts as a skid when the machine is alighting on or taking off from land, and performs the function of a water rudder when the machine is operating on the sea. It is formed of steel plate, and sprung by rubber shock absorbers. The two wing tip floats are built-up of a framework of duralumin covered with mahogany.

Whatever are the results obtained in the competition, Messrs. Beardmore and Co. are to be congratulated upon their courage in making such a radical departure from orthodox design and tackling a problem which must be attacked sooner or later, and one wishes them every success. That the machine is a bold experiment may be admitted, incorporating as it does a number of more or less unknown quantities, such as duralumin construction and transmission drive to the propellers, features which may, and probably will, require lengthy experiments before being successfully developed, but at a time like the present, when so many firms are withdrawing from the industry on account of no immediate profits being forthcoming, it is refreshing to see a firm which is not afraid of looking ahead, and which has the foresight necessary to set out boldly to break new ground, knowing that immediate success - and its reward - is not likely to be arrived at. We think that this attitude on the part of a firm of this standing augurs well for the future of commercial aviation.

- Flight, September 1920

THE AIR MINISTRY SEAPLANE (AMPHIBIAN) COMPETITION

Фотографии

-

Flight 1920-09 / Flight

THE AIR MINISTRY AMPHIBIAN COMPETITION: Our photograph shows the hull (inverted for planking) of the Beardmore W.B. IX flying boat

-

Flight 1920-09 / Flight

THE AIR MINISTRY AMPHIBIAN COMPETITION: The Beardmore W.B.IX Flying Boat, four 200 h.p. Beardmore engines. Longitudinal and transverse sections of the hull.

- Фотографии