Фотографии

-

Committed to producing large numbers of Whitleys (Mk.V illustrated), Armstrong Whitworth’s had to find another site to undertake to complex process of building Ensigns.

Самолёты на фотографии: Armstrong Whitworth Whitley / A.W.38 - Великобритания - 1936

-

Регистрационный номер: G-ADSR [5] Sister company Armstrong Siddeley not only made fine aero engines at the Parkside plant in Coventry but excellent cars and the appearance of G-ADSR ‘Ensign’ was used to great effect in marketing the latter.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Регистрационный номер: G-ADSR [5] Problematical though the AW.27 may have been, it was undoubtedly an attractive-looking machine when the undercarriage did eventually retract and it got to height!

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Manoeuvring the fuselage of what is believed to be No.1 from its jigs and into the main assembly hall - with the river that gave the aerodrome its name in the background. Note the jury-rigged wheels to move the stressed skin monocoque fuselage around, with the ‘main wheels’ attached to where the spar would sit.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

A view of No.1 also on July 7, 1937, this time from behind the trailing edge of the port wing, the film speed in the camera not coping with the movements of the workforce even though it appears most of them have been ‘tipped off’ and told to ‘hold it’! From the aft face of the huge box spar the wing was to be fabric covered.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

A view from the front of No.1, taken on August 18, 1937 showing the workbenches for detail assembly and rectification in the foreground. All four Tigers are now in place, with the outer two cowled. Fuel tanks occupied the leading edges between the engines, between the inner engines and the wing root and outboard of the outer Tigers.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

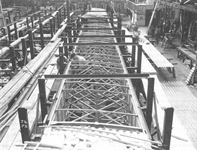

Wing spars lying in their forming up jigs. The spar was built in three parts (centre and two outers) and was made from light alloy with internal bracing. Behind to the right is a fuselage under way and in the background to the left the oval section frames that made up the fuselage are on their wooden pattern jigs.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Work in hand on the port wing of No.5, February 2, 1938. Two engine bearers in the foreground on the plank work platform, while the outer leading edge tank has been installed.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Регистрационный номер: G-ADSV The spar of No.5 (c/n 1160 G-ADSV ‘Explorer’) under assembly. Such a construction would not have looked out of place in a shipyard! In the foreground are jig tables for the oval-section fuselage frames and for the moving flying surfaces. The wooden balcony in the background was where the ‘looking down’ shot of the spars was taken from.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Регистрационный номер: G-ADSW Work under way on the wing spar of No.6 (c/n 1161 G-ADSW ‘Eddystone’), August 18, 1937. The box spar format and internally-braced structure is evident - as is the depth of the spar, witness the man standing in it!

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

The port wing of No.1, taken September 24, 1937. In the foreground can be seen was the largest pre-1939 aircraft tyre - all 6ft 3in (1.9m) diameter of the mainwheel. The huge main undercarriage construction retracted rearwards into the wing and was designed to do so it what must have been an agonising 90 seconds during the climb out. Try as Armstrong Whitworth and Automotive Products (who made the hydraulic jacks for the undercarriage and other functions in the Ensign) might, this time was seldom achieved and the legs were determined to retract asymmetrically.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Регистрационный номер: G-ADSS, VT-AJE A view of the assembly shop, July 7, 1937. The huge, bridge-like inner portion of the main spar has been settled into place on the fuselage of No.2 (c/n 1157 G-ADSS at that point destined for Indian Trans-Continental Airways as VT-AJE ‘Ellora’) while the starboard out section of spar is readied for mating up. To the right is the nose section of what is believed to be No.3.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Work in progress on the tail section, August 18, 1937. The A W.27 was 23ft (7.01m) high when sitting on its tailwheel.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Регистрационный номер: G-ADSR [5] ‘Ensign’, the prototype AW.27, is lent scale by the large crowd gathered, presumably at the roll out, January 1938. It carries neither its name nor Imperial Airways lettering.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Регистрационный номер: G-ADSR [5] As with the remainder of the fleet, with wartime came camouflage and the 'underlining' of the registration letters in red, white and blue. ‘Ensign’ joined BOAC in April 1940 and was converted to Mk II status. After only 2,099 hours flying time, it was withdrawn at Almaza, Cairo, in September 1944 and eventually scrapped there.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Регистрационный номер: G-ADSR [5] July 7, 1937 and work on the first Ensign (c/n 1156, the flagship G-ADSR) is well under way. At this point the 123ft (37.49m) monster was 202 days from first flight. Note the access platforms, an ad hoc collection of scaffolding poles and wooden beams. The port out Armstrong Siddeley Tiger IXC has been ‘hung’.

Самолёты на фотографии: Armstrong Whitworth Ensign / A.W.27 - Великобритания - 1938

-

Регистрационный номер: G-ABPI, VT-AEF As witness the comparison table, while the AW.15 Atalanta shared a similar format with its successor, it was a substantially smaller airframe.

Самолёты на фотографии: Armstrong Whitworth Atalanta / A.W.15 - Великобритания - 1932

Статьи

- Round-Out

- B.Cumming - Triple DSC

- B.Riley - 'A Coming Together'

- D.Henley - Jet Age (1)

- D.Nicolle, G.Cattaneo - "A Delight to Fly"

- F.Prins - Homage to the Vanguard

- K.Conboy - From Flying Club to Front Line

- R.Bonser, K.Ellis - Cuckoo in the Nest

- S.Day - Twice in the Front Line

- T.Buttler - Early Wing-Swingers

- W.Jesse - Budd's Covered Wagon