Варианты

- PWS - PWS-21 / PWS-24 - 1930 - Польша

- PWS - PWS-54 - 1933 - Польша

Flight, August 1933

THE P.W.S-54

A Polish High-Speed Commercial Aeroplane

IN March last, the I.B.T.L. (the Polish Aero Research Institute) completed, with satisfactory results, the flight testing of the P.W.S.54 plane, designed and built for the Polish Ministry of Communication by the Podlasian Aircraft Manufacturing Company of Warsaw.

This aeroplane is one of the fastest of commercial planes of this type built in Poland, and the performance attained with the Skoda-Wright J.5 220-h.p. engine equals the performance of many of the best planes of other nations. At the present time the P.W.S.54 is being tested by the Polish Airlines "Lot," where its serviceability may be proven to the utmost.

The P.W.S.54, succeeding the models P.W.S.20, 21 and 24, is the fourth commercial plane designed and completely manufactured by the Podlasian Aircraft Manufacturing Co. The good results obtained with this machine were due, to a large extent, to the presence of an efficient wind tunnel designed for the company by Prof. Witoszynski. All experimental data were procured in this tunnel, including the best possible arrangements of cowlings, fairings, etc. The final model tests were conducted in the laboratories of the Aerodynamic Institute of the Warsaw Politechnical School.

The weight empty (2,070 lb.) applies only to the experimental model, where unnecessary weight was added as a consequence of late changes and the use of two coats of varnish and two coats of lacquer on the inside of the wings. In production there is now used only one coat of special lacquer for the same purpose. It is guaranteed that the weight empty on the ensuing planes will not exceed 2,000 lb.

The P.W.S.54 is a high-wing, internally-braced monoplane of steel tube construction with wooden wings. To obtain the maximum possible performance, the drag of the plane was reduced to a minimum through wind-tunnel tests of a complete model and individual parts. In addition to obtaining high aerodynamic efficiency, pains were taken in designing every detail of construction to give the least possible drag. As a consequence all control horns, cables, etc., are buried. The control cables are conducted in a special channel in the bottom portion of the fuselage, with access to them by means of laces.

All important control assemblies have been grouped under the pilot's floor. For inspection it is only necessary to unfasten one cover plate.

The passenger compartment is separated from the pilot's compartment, but a sliding door makes entrance possible from one to the other. The passengers' compartment, although seemingly small (41 in. x 49 in. x 71 in.), permits a comfortable seating arrangement for four persons. Two seats are placed in the forward portion, one of them folding to give access to the pilots' compartment.

One double seat is located in the rear of the cabin.

In the centre portion of the passenger compartment, a cut-out in the lower wing surface just above the doors increases the head-room from 49 in. to 55 in. One door on each side of the cabin, provided with retractable steps, offers a comfortable means of entrance. Windows are opened and closed by rotating them about a horizontal axis. There are two baggage compartments, both located just aft of the cabin, one of which is accessible during flight from within. Air is heated by exhaust gases and circulated throughout the cabin.

The pilot's compartment, accommodating one, is entirely closed in; and has a high degree of visibility. The seat is adjustable by means of a hand-operated lever. The instrument board is suspended on rubber-mounted bearings. The pilot's side window may be opened by rotating it about its horizontal axis, thus offering the pilot additional visibility in landing. The control system consists of a control wheel and pedals. All movable joints in the control system are composed of self-adjusting ball bearings. The stabiliser adjustment is located to the right and above the pilot. Bendix brakes are operated directly from the rudder pedals.

The fuselage is of welded steel-tube construction with cross tie-rods in the rear portion, fabric covered. A balloon tyre tail-wheel is used.

The wings are of wood, internally braced, with two box spars and stressed plywood. Near the tips a decalage of 2 deg. is incorporated into the design as a safeguard from spinning.

The tail unit is of welded steel-tube construction, fabric covered. The elevator is balanced. The chassis is of a special type, the wheels being mounted on a fork. The wheel fairing is in two parts, folding back for inspection and removal of the wheel. The shock-absorbing unit is of the oleo-pneumatic P.Z.L. type.

The engine mount is of welded steel-tube construction, attached to the fuselage on rubber bearings. The cowling is fastened with special clips offering no drag.

Fuel tanks are located in the wings on both sides of the fuselage, their capacity being 85 gallons.

- Flight, August 1933

THE P.W.S-54

Фотографии

-

Flight 1933-08 / Flight

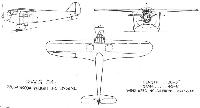

Регистрационный номер: SP-AHY [4] THE P.W.S.54: The side view show the general lines of this new Polish machine. The engine is a Skoda-built Wright J-5.

-

Aeroplane Monthly 1991-06 / J.Stroud - Wings of Peace

Регистрационный номер: SP-AHY [4] Prototype and the only example Polish PWS-54 (SP-AHY) on the snow-covered aerodrome during the winter 1932'33. Note ringed insigne of P.L.L. LOT on the fin.

-

Flight 1933-08 / Flight

Регистрационный номер: SP-AHY [4] FOR EASY INSPECTION: The "spats" over the wheels are hinged so that mud can be removed from the fork and wheel with a minimum of trouble.

-

Flight 1933-08 / Flight

Регистрационный номер: SP-AHY [4] -

Flight 1933-08 / Flight

P.W.S.54. 220 hp Skoda-Wright J-5 Engine

- Фотографии