Варианты

- Hendy - Hendy 302 - 1929 - Великобритания

- Parnall - Hendy Heck - 1934 - Великобритания

- Parnall - Model 382 / Heck III - 1939 - Великобритания

Flight, March 1939

MODERNITY in a TRAINER

Advanced Features of the Parnall 382 : Slots and Slotted Flaps

IN the Heck cabin monoplane, a few years ago, Mr. Basil B. Henderson demonstrated what could be done by combining Handley Page slots and slotted flaps with good aerodynamic and structural design. All the best features of the Heck have now been reproduced in a new ab initio training machine which has given a very satisfactory account of itself in trials at Yate aerodrome and Martlesham Heath.

The Parnall 382, as the type is designated, has been produced for ab initio training and conforms in many respects to an Air Ministry specification. Characteristics worthy of special note are the high-lift devices and the facilities for inspection. The engine is a Gipsy Six Series II driving a Schwartz-finished wooden airscrew.

The wing, undercarriage and tail unit are almost identical with those of the Heck. Serviceability of these components is guaranteed by the fact that two Hecks have been in continuous use on the company’s business for three years, and at no time has either been unserviceable for more than half a day on each normal twenty-five hour inspection.

Tapering in plan form and thickness, the cantilever wing is built in three sections. The outer sections carry Handley Page automatic slots, and flaps are fitted along 80 per cent, of the trailing edge. The inner sections of the flaps can be depressed to an angle of 45 degrees, while the outer portions, which function as ailerons, can be lowered about 15 degrees, still operating normally as ailerons when depressed to the fullest extent. Manual operation is provided for the flaps, permitting setting at any position between zero and maximum depression. The flap and aileron hinges are located beneath the wing on outriggers which transfer the load reaction to the main structure. The slots are of the automatic type and run on three tracks, supported on roller bearings. They are quite independent of the flap gear and are held closed bv light springs. A locking device is fitted in the instructor's cockpit.

There are two main wing spars of "I" section with spruce flanges and plywood webs, the latter having spruce stiffeners at frequent intervals. The ribs have spruce flanges with spruce posts gusseted to them to form the internal bracing. Plywood covering is used for the entire wing.

Spruce longerons and plywood sides characterise the fuselage. The sides are assembled as complete units and the fuselage structure is formed in the assembly jig, with bulkheads at suitable intervals. Actually, the fuselage is in two halves, the junction being aft of the rear cockpit.

The tailplane is fixed to the top longerons by steel-plate fittings, horizontal trim being adjusted by tabs on the trailing edge of the elevator, and the elevator hinges are so arranged that there is practically no gap at the junction with the tailplane. Constructed as a unit, the fin is attached in such a manner that the side loads are transferred to the fuselage at the fin post and at another point two bays further forward. The rudder is hinged to the fin post in a similar manner to that used for the elevator-tailplane joint. There is no aerodynamic balance and the mass balance weights are carried on streamline tubes attached to the rudder spar at its top end. The tailplane and fin are plywood covered, but the rudder and elevators are of wooden construction with fabric covering.

Although resembling that of the Heck, the cantilever undercarriage is not splayed out. It incorporates Lockheed legs and Parnall forks and is carried on the centre section spar by built-up duralumin fittings bolted to the spar at the wing joint fittings. The fairings have been designed to provide additional stiffening against braking loads. Dunlop hydraulic brakes are fitted, being operated by a hand lever on the port side of the pilot’s seat. Differential control is provided from the rudder bar.

The welded engine mounting is attached to the front of the fuselage by four bolts, and since quick-release couplings are incorporated in each pipe line, engine changing is very rapid.

The layout of the two tandem cockpits is almost identical. Since the front cockpit, which is occupied by the pupil, is used during solo flights it accommodates all the starting controls and electrical equipment. A dummy undercarriage retraction control and folding blind flying hood which, when raised, fits inside the windscreen, are also fitted. The “Bungee“-loaded parachute-type seats have a four-inch vertical adjustment and may be moved fore and aft over a range of two inches.

The flaps are operated through a screw jack arrangement with Teleflex controls, the flap-operating wheel sharing the same shaft as the tab control. Four turns of the wheel will lower the flaps completely, intermediate settings being indicated on the control panel. The tabs also have Teleflex controls and are actuated through a torque shaft in the tailplane.

The rear (instructor’s) cockpit may have a sliding coupe roof which is calculated to benefit not only the temper of the occupant but the performance of the machine. A brake cut-out lever is another comforting feature.

The particularly neat Perspex windscreens are explained by the company’s moulding experience in connection with the Nash and Thompson gun turrets.

Thirty-six gallons of petrol - sufficient for a cruising duration of three hours - is carried in two wing tanks, the gauge being under a Perspex window in the wing. The three-gallon oil tank will, in production machines, be mounted in the leading edge.

Inspection doors are located over the whole length of the fuselage and at appropriate points in the wing.

Data for the Parnall 382 Trainer are: Span, 33ft. 8in.: length, 28ft. 9 1/2 in. ; track, 6ft. 10in. ; wing area, 155 sq. ft.; wing section, B.H.5 ; tare weight, 1,655 lb.; all-up weight, 2,450 lb.; top speed, 155 m.p.h.; take-off run, 180 yd.

Mr. Henderson tells us that, by using the slots and flaps the machine can be flown at 43 m.p.h. with the engine on. The stall is not reached until the angle of incidence is over 30 degrees, eliminating the possibility of accidental stalling on the glide. Mr. J. A. C. Warren, the company's test pilot, has dived the machine up to 265 m.p.h

Описание:

- Flight, March 1939

MODERNITY in a TRAINER - Flight, September 1939

To-day's Light Aeroplanes - Flight, November 1939

Britain's Military Aircraft

Фотографии

-

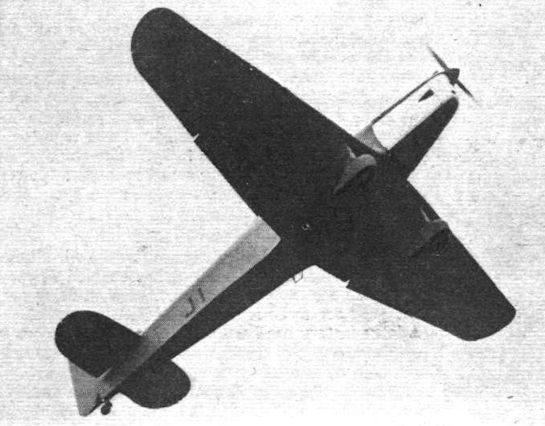

Flight 1939-09 / Flight

The prototype 382 in the air. Notice that it is being flown solo from the front seat.

-

Flight 1940-12 / Flight

The Parnall 382 trainer (Gipsy Six) has Handley Page slots and slotted flaps.

-

Flight 1940-03 / Flight

The rather more powerful Henderson Trainer;

-

Flight 1939-11 / Flight

A new training aircraft which has acquitted itself well in trials is this attractive Parnall monoplane. The engine is a D.H. Gipsy Six. In the version shown the rear cockpit is enclosed.

-

Flight 1939-03 / Flight

Mr. B. B. Henderson, the designer, with Mr. J. A. C. Warren, test pilot - whose headgear tempts us to pin a quip on his name.

-

Flight 1939-08 / Flight

A view from the control tower of a small section of the large crowd at Wilmington last Saturday. In the background can be seen a B.F.W. M-35, Tipsy, Wicko and the new Parnall Trainer.

Другие самолёты на фотографии: Foster Wikner Wicko - Великобритания - 1936Messerschmitt BFW M.35 - Германия - 1933Tipsy B / BC - Бельгия - 1937

-

Flight 1939-09 / Flight

The slots, flaps and ailerons of the new Parnall trainer. Both flaps and ailerons are slotted.

-

Flight 1939-03 / Flight

"Slottery and flappery" is an important feature of the Parnall’s specification. The inner portions of the flaps can be depressed to 45 deg. and the outer portions, which function as ailerons, can be lowered about 15 deg. The other appendages are the numerous inspection doors, shown open.

-

Flight 1939-03 / Flight

The Headmaster’s Study: Believing that both instruction and performance will benefit, Mr. Henderson has designed this coupe enclosure for the instructor’s cockpit. The blind-flying hood is folded neatly down inside the front cockpit.

-

Flight 1939-03 / Flight

Details of the undercarriage and its attachment to the front spar. The spat is divided transversely.

-

Flight 1939-03 / Flight

Parnall 382 (Gipsy Six Series II)

- Фотографии