Описание

Страна : Великобритания

Год : 1937

Двухместный туристический и учебный самолет

Варианты

- De Havilland - Swallow Moth / D.H.81 - 1931 - Великобритания

- De Havilland - Moth Minor / D.H.94 - 1937 - Великобритания

Moth Minor / D.H.94

de Havilland DH.94 Moth Minor

Еще 24 августа 1931 года фирма провела испытания единственного экземпляра самолета DH.81 Swallow Moth - низкоплана с открытой двухместной кабиной, оснащенного двигателем Gipsy IV мощностью 80 л. с. (60 кВт). Из-за большого количества заказов на другие варианты Moth работы по этому проекту прекратили, чтобы возобновить несколько лет спустя, но с учетом новых технологий, опробованных при создании DH.88 и Albatross. Прототип цельнодеревянного DH.94 Moth Minor впервые взлетел в Хэтфилде 22 июня 1937 года. Было развернуто серийное производство, и до начала Второй мировой войны построили 71 самолет, в том числе четыре в варианте Moth Minor Coupe, с более высокой хвостовой частью фюзеляжа и откидывающейся крышей кабины. В начале 1940 года, когда производство в Хэтфилде было загружено выпуском боевых самолетов, чертежи, комплектующие и построенные планеры Moth Minor были переданы "de Havilland Aircraft Pty Ltd" в Бэнкстауне, Сидней. Там были выпущены более 40 машин для австралийских ВВС.

ТАКТИКО-ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

de Havilland DH.94 Moth Minor

Тип: двухместный туристический и учебный самолет

Силовая установка: один рядный поршневой двигатель de Havilland Gipsy Minor мощностью 90 л. с. (67 кВт)

Летные характеристики: максимальная скорость на оптимальной высоте 190 км/ч; крейсерская скорость на оптимальной высоте 161 км/ч; начальная скороподъемность 180 м/мин; потолок 5030 м; дальность полета 483 км

Масса: пустого 446 кг; максимальная взлетная 703 кг

Размеры: размах крыла 11,15 м; длина 7,44 м; высота 1,93 м; площадь крыла 15,05 м2

Описание:

- Moth Minor / D.H.94

- Flight, October 1938

British Sport and Training types - Flight, June 1939

MOTH SUCCESSOR - Flight, September 1939

To-day's Light Aeroplanes

Фотографии

-

Мировая Авиация 214

Регистрационный номер: G-AFPN [6] На снимке изображен G-AFPN - хорошо заметен характерный для Moth Minor большой перфорированный воздушный тормоз под центропланом, позволявший в том числе сократить посадочную дистанцию.

-

Мировая Авиация 214

Регистрационный номер: G-AFNG [10] Часть Moth Minor строилась в варианте «купе» с откидным фонарем кабины, другие самолеты были переоборудованы по стандарту Moth Minor Coupe. G-AFNG - представитель последнего типа, его переоборудование было выполнено в 1954 году в Великобритании.

-

Aeroplane Monthly 1999-06 / J.Maynard - Spring-cleaning the hall /Mosquito aircraft museum/

Регистрационный номер: G-AFOJ [5] The beautiful Moth Minor coupe. The line was brought to an end in Britain by the outbreak of the Second World War, but this particular example was used by the company both for communications and propeller test work until 1949 when it passed to the London Aeroplane Club.

-

Air-Britain Archive 1986-04

Possibly the earliest view of the design? This is very similar to that of 18.8.37 on p.85/84 but without windshields at all. Engine rotation is the opposite of the Gipsy Minor, ie: it is anticlockwise from the front, clockwise from the pilot's viewpoint.

-

Air-Britain Archive 1985-03

The first Moth Minor photograph in our collection was taken on 18.8.37 two months after first flight. The cockpit shape can clearly be seen to have been modified by infilling but the original shape matches drawings of the open-cockpit DH.81. This may merely be due to the coincidence of designer but there is another common factor. Behind the engine cowling there appears to be a hole which relates closely to the position of attachment points for the braced Swallow Moth style undercarriage. Clearly visible is the tailwheel position forward of the rudder (the DH.81 had a skid not a wheel) and also the anticlockwise propeller rotation.

-

Air-Britain Archive 1988-01

The same aircraft as shown in the centre of p.85/84, photo no. is DH.110A so the date must be 1.10.37. It clearly shows the raised tailplane and bulbous fairing ahead of it. The cockpit sides are high as previously noted and the strange baffle on top of the cowl is clearly visible.

-

Air-Britain Archive 1985-03

Next we see further modifications to the same aircraft as at 1.10.37. The tailplane has been raised well clear of the rear fuselage decking and the original location of the bracing strut is clearly visible on the lower fuselage. The cockpit sides have again been modified, this time to a less rounded profile, and a mysterious addition has been made to the top of the cowling - perhaps a thin baffle or cooling device? The propeller apparently still rotates anticlockwise and the tailwheel remains unchanged.

-

Air-Britain Archive 1985-04

We have now obtained from BAe via Maurice Marsh this view of an intermediate stage. With a date of 13-10.37, this clearly shows the mid-position tailplane with the coupe top added. In front of the tailplane is a new fairing which is open at the rear. Certainly we can feel more confident that the two lower photos on p.85/84 are of the same aircraft. However, a article in "Popular Flying" of 12.38 said that "For over a year now experimental examples of this machine have been test flown almost daily." and also mentions "an extensive programme of test flights".

-

Air-Britain Archive 1988-01

The coupe version with the same style of raised tailplane. This is the aircraft shown on p.85/119 and is photo DH.115B of 13.10.37. Were the two types being test flown simultaneously or was the open cockpit version converted to coupe and repainted within twelve days?

-

Air-Britain Archive 1986-04

This coupé appears to be identical to the October 1937 version on p.85/84. It has the same engine rotation as all these pre-Gipsy Minor examples. Further comments on these or the original photos would be welcome.

-

Air-Britain Archive 1985-03

Chronologically, the next photograph is of an unmarked coupe version, dated 29.10.37. Only the front cockpit is glazed and in this form the aircraft could surely not be flown from the rear - in any case it was normal procedure to fly the Moth Minor from the front cockpit. The nature of the modification makes it more likely that this was intended to test the aerodynamics of an enclosed cockpit version. Some rather crude wiring can be seen below the cockpit, possibly for airflow or wing loading tests? This certainly seems to be the same aircraft as in the earlier photos, the propeller rotation is definitely anticlockwise, the tailwheel position is unchanged but the tailplane has returned to the lower position.

-

Air-Britain Archive 1985-03

The coupe marked E6 must be the same aircraft as the one above. In every way major and even minor features match, with the obvious exception of the small section of fin removed. This cannot be related to the raised tailplane position in the previous shot as it is noticeably higher, either the result of further tailplane experiments or a reduction in fin area. No date is known, but from negative numbers it would seem to be quite soon after the last photo, however "under B Conditions" quotes E6 as being in use from 6.38.

-

Air-Britain Archive 1985-03

Next we have the photograph of three different Moth Minors - as shown in Air-Britain DIGEST of July/August 1983 in the 'What Do You Know?' feature. In the foreground E6, if it is the same aircraft, has been stripped of the canopy and decking but retains a streamlined headrest to the rear cockpit. The dorsal fillet and thicker wing root are clearly identifiable, the tailwheel has been moved to the rear of the fuselage box section but the propeller rotation is still apparently anticlockwise.

In the centre E7 shows standard production coupe features, other than the absence of anti-spin strakes. We are told that the true coupe version flew experimentally in the summer of 1938 and was changed little in production. This photo clearly shows clockwise rotation of E7 and E8 which indicates production engines (ie: post 3.39), while E6 is said to have become G-AFSD in 5.39, possibly these points provide an approximate dating for the picture. On the third aircraft the registration is obscured but the colour scheme is sufficiently unique and is identical to other published photos of E8 taken between 7.38 and 8.39. Although it is unidentified E8 could be one of the early production aircraft which went overseas - do we have photos which could suggest or eliminate any possible candidates? -

Air-Britain Archive 1988-01

Yet another variant! This time we have a faired canopy over the rear cockpit only, a style which was to be developed later into the tricycle undercarriage version of 4.40. This version looks very similar to the E-6 shown on p.85/119 and is photo no. DH.253A indicating a later model than the others, possibly late 1938 or early 1939. None of these examples appear to have production Gipsy Minor engines. Has anyone any comments to add?

-

Air-Britain Archive 1986-04

This looks much like E6 as shown on p.85/119 but the cockpit windscreens seem to extend much lower than on other examples and the tailwheel is placed forward of the sternpost.

-

Air-Britain Archive 1985-04

The photograph, via A.J.Jackson and Peter Green, shows a very crudely-marked E6. This version has a production engine (post 3-39), undercarriage raked forward, production-style cockpits and tailwheel - but the base of the rudder does not seem quite right and the horizontal tailplane is not as high as on production machines. In the background are camouflaged Tiger Moths - can this help in dating the winter scene?

Другие самолёты на фотографии: De Havilland Tiger Moth / D.H.82 - Великобритания - 1931

-

Air-Britain Archive 1986-03

Two further photos of pre-production aircraft, both from "The Aeroplane" via Jack Meaden. Here is the unidentified E8 with Capt Geoffrey de Havilland in the foreground, the date 5.10.38 on the back may refer to publication date.

-

Jane's All the World Aircraft 1938 / 03 - All the world's aeroplanes

The D.H. "Moth-Minor" Two-seat Light Monoplane (90 h.p. D.H. "Gipsy-Minor" engine).

The photograph was used in "Aeroplane" of 3-8.38 and shows E8 in the same colour scheme as in our group photo. -

Flight 1939-06 / Flight

Another view of the production Minor in the air. The crew are demonstrating hands-off formation flying - or the pilot may only be trying to warm his ears in this flaming June.

-

Flight 1939-03 / Flight Advertisements

The new Moth can be flown solo front either seat without ballast. This picture was taken from the ground.

-

Flight 1939-03 / Flight Advertisements

The inverted-flying picture was secured at close range and emphasises the stability of the new Moth in aerobatic training.

-

Flight 1938-08 / Flight

C.A.G. PROTOTYPE: The open-cockpit version of the new D.H. Moth Minor. Its form will be familiar to regular Hatfield visitors, since this and a cabin version has been in and out of the air for the past year. From its inception the D.H.94 has been the special interest of Capt. Geoffrey de Havilland himself, and, with the Air Guard scheme in action, it will now have its chance.

-

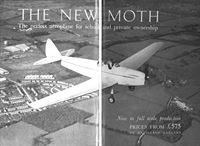

Flight 1938-08 / Flight Advertisements

Following two years of development and test, and created out of the company’s accumulated experience of thousands of Moth aircraft in world-wide use, The de Havilland Aircraft Co., Ltd., announces the Moth Minor, a light aeroplane for training and personal ownership, of robust construction and superior performance, and combining exemplary flying qualities and ease of piloting with a new low level of first and running costs. Deliveries will commence in the Spring of 1939. For sheer reliability the Moth Minor is fitted with a Gipsy engine, the new 90 h.p. GIPSY MINOR

-

Air-Britain Archive 1985-04

"Flight" used the view of E8 on 4.8.38 showing it in a 'clean' paintscheme and which we can only assume was taken earlier that the others. In this view the cowling shape and the presence of the possible attachment points are notable pre-production features.

-

Flight 1939-03 / Flight Advertisements

The new Moth is stable about all axes and was flown hands-off for the photograph which was taken at close quarters. It may be cruised indefinitely with hands and feet off the controls.

-

Flight 1939-03 / Flight Advertisements

The Moth Minor and its Gipsy Minor engine: simplicity born of a vast experience.

-

Flight 1939-08 / Flight

The air-brake usefully steepens the approach, but is not too effective for ab initio training purposes.

-

Flight 1939-03 / Flight Advertisements

A true impression of the reserve power available for take-off and climb is given by this genuine photograph showing the performance on full load.

-

Aeroplane Monthly 1980-08 / De Havilland D.H.94 Moth Minor G-AFNG /Preservation Profile/

Регистрационный номер: G-AFNG [10] -

Aeroplane Monthly 1980-08 / De Havilland D.H.94 Moth Minor G-AFNG /Preservation Profile/

Регистрационный номер: G-AFNG [10] -

Air-Britain Archive 1985-04 / Impressment Review (23)

Регистрационный номер: G-AFNG [10] From Bernard Martin's collection comes this early postwar view of Taylorcraft Plus C G-AFUA. The aircraft was stored during the war but had only a short subsequent career as it crashed on 18.10.48 at Northaw, Middlesex. Also present at the anonymous location is Moth Minor G-AFNG and a Messenger, so we can put the date between 11.46 and 10.48.

Другие самолёты на фотографии: Taylorcraft A / B / C / F-19 / F-21 / F-22 - США - 1937

-

Jane's All the World Aircraft 1980 / Encyclopedia of Aviation - Aircraft A-Z - v3

Регистрационный номер: G-AFOZ de Havilland D.H.94 Moth Minor.

-

Air-Britain Archive 1985-02 / Impressment Review (21)

Регистрационный номер: G-AFPC [4] Снимок демонстрирует отличную устойчивость Moth Minor - оба пилота сняли руки с управления.

No apologies for using this well-known view of the RAF Flying Club's G-AFPC being flown with four hands off! -

Flight 1939-09 / Flight

Регистрационный номер: G-AFPC [4] Moth Successor: The new D.H. Moth Minor, which is an inexpensive machine for touring and training. It is normally flown from the front seat.

-

Flight 1939-08 / Flight

Регистрационный номер: G-AFPC [4] -

Flight 1939-08 / Flight

Регистрационный номер: G-AFPC [4] An unusual view of the Minor, showing its distinctive plan form.

-

Air-Britain Archive 1982-01 / U.K. C of A Applications (9)

Регистрационный номер: G-AFPN [6] One of the batch of Moth Minors listed above, G-AFPN was caught by Bernard Martin's camera at Shoreham on 29.8.66.

-

Air-Britain Archive 1985-03 / Impressment Review (22)

Регистрационный номер: G-AFPN [6] Superbly turned-out Moth Minor G-AFPN photographed at its Denham base on 6.6.70 by John Ware.

-

Air Pictorial 1977-05 / T.Norman - Strathallan Collection

Регистрационный номер: G-AFPN [6] The Strathallan Collection includes a fair cross-section of de Havilland types: Moth Minor G-AFPN.

-

Aeroplane Monthly 1978-09 / News Spotlight from Strathallan

Регистрационный номер: G-AFPN [6] Duncan Simpson in Strathallan's beautiful little Moth Minor, G-AFPN.

-

Aeroplane Monthly 1983-06 / P.Jarrett - Grapevine

Регистрационный номер: G-AFPN [6] Some of the lighter types on view at Duxford before the Christie's auction. Moth Minor, Tiger Moth and Gemini nearest.

Другие самолёты на фотографии: De Havilland Tiger Moth / D.H.82 - Великобритания - 1931Miles Gemini M.65 / Aries M.75 - Великобритания - 1945

-

Air-Britain Archive 1985-03

Регистрационный номер: G-AFTH, HM585 A final comparison with the earlier side views is this shot of G-AFTH c/n 94040 which was used by the manufacturers as a communications aircraft before being impressed as HM585 in October 1942.

-

Air Pictorial 1957-03 / Air Pictorial's photo-review

Регистрационный номер: HB-OMU A pre-war de Havilland D.H.94 Moth Minor (c/n. 94020) two-seater (90-h.p. Gipsy Minor I), owned by Cercle Aerophile Geneve. Sole Swiss D.H.94.

-

Aeroplane Monthly 1978-01 / P.Anderson - Moth Monoplane

Регистрационный номер: VH-ACS [2] -

Aeroplane Monthly 1978-01 / P.Anderson - Moth Monoplane

Регистрационный номер: VH-ACS [2] VH-ACS made its first flight at Hatfield on August 14, 1939. As a result of some confusion with a sister aircraft during wartime repairs, it now carries the erroneous c/n 94072 instead of 94047, its true identity.

-

Aeroplane Monthly 1985-10 / D.H.94 Moth Minor A21-38/VH-AIB /Preservation Profile/

Регистрационный номер: VH-AIB [3], A21-10 [3] VH-AIB at Berwick, Victoria in March 1970.

-

Aeroplane Monthly 1985-10 / D.H.94 Moth Minor A21-38/VH-AIB /Preservation Profile/

Регистрационный номер: VH-AIB [3], A21-10 [3] The same aircraft at Point Cook, in November 1977.

-

Aeroplane Monthly 1985-10 / D.H.94 Moth Minor A21-38/VH-AIB /Preservation Profile/

Регистрационный номер: A21-10 [3], VH-AIB [3] -

Air-Britain Archive 1983-03 / 3 - New Zealand /Complete Civil Registers/ (10)

Регистрационный номер: ZK-AKM The only Moth Minor currently airworthy in New Zealand, ZK-AKM at Timaru on 21.5.71.

-

Air-Britain Archive 1983-04 / 3 - New Zealand /Complete Civil Registers/ (11)

Регистрационный номер: ZK-ALN Moth Minor ZK-ALN on a visit to Rotorua in the mid-sixties.

-

Air-Britain Archive 1988-01 / 3 - New Zealand /Complete Civil Registers/ (26)

Регистрационный номер: HM579, ZK-BFP Moth Minor ZK-BFP in quasi-military markings at Christchurch on 10.9.78.

-

Air-Britain Archive 1985-03

Регистрационный номер: ZS-ARE [3] The South African demonstrator ZS-ARE c/n 94005 showing that antispin strakes were fitted to even the earliest production aircraft though not to the three in the previous photo.

-

Flight 1939-06 / Flight

Регистрационный номер: ZS-ARE [3] The Moth Minor in its final production form. This particular machine is one for South Africa.

-

Flight 1939-08 / Flight Advertisements

Регистрационный номер: ZS-ARE [3] -

Flight 1939-06 / Flight

TWO MASTERS AND A MINOR: Mr. J. A. Harris (right) who is chief instructor of the London Aeroplane Club, and Mr. J. Goodyear, his principal assistant, take over the first of their six Moth Minors. The club at present has nine Tiger Moths and three Hornet Moths. Incidentally, these two pilots' names were included in the G.A.P.A.N.’s first list of Master Instructor’s Diploma recipients. Both were in the Royal Air Force and both took instructor’s courses at the C.F.S.

-

Flight 1939-03 / Flight Advertisements

In the starboard stub wing there is a large locker for luggage which may alternatively be used for an extra fuel tank, doubling the range.

-

Flight 1939-03 / Flight Advertisements

The wings of the new Moth are extremely easy to fold and give an overall folded width of only 12 ft. - an important item in housing economy.

-

Jane's All the World Aircraft 1947 / All the world's aeroplanes

The de Havilland Factory and Aerodrome at Rongotai, New Zealand. The aircraft are D.H. Dominies, with a Fox Moth, a Puss Moth, a Moth Minor, and a Tiger Moth in the foreground.

Другие самолёты на фотографии: De Havilland Dragon Rapide / Dominie / D.H.89 - Великобритания - 1934De Havilland Fox Moth / D.H.83 - Великобритания - 1932De Havilland Puss Moth / D.H.80 - Великобритания - 1929De Havilland Tiger Moth / D.H.82 - Великобритания - 1931

-

Jane's All the World Aircraft 1938 / 03 - All the world's aeroplanes

The D.H. "Moth-Minor" Two-seat Light Cabin Monoplane (90 h.p. D.H. "Gipsy-Minor" engine).

-

Air-Britain Archive 1986-03

Two further photos of pre-production aircraft, both from "The Aeroplane" via Jack Meaden. An air-to-air view of coupe E7 which was c/n 9405, although we did express the possibility that two coupes may have carried this marking.

-

Flight 1938-08 / Flight

CABIN VERSION: The new Moth Minor, which should be in production early next year, in its cabin form. It is a tandem-seater in which the pilot sits ahead, with a really good view forwards and over the leading edge.

-

Jane's All the World Aircraft 1938 / 03 - All the world's aeroplanes

The D.H. "Moth-Minor" Two-seat Light Cabin Monoplane (90 h.p. D.H. "Gipsy-Minor" engine).

-

Aeroplane Monthly 1983-02 / L.Curtis - Flying for all

During 1939 production of the D.H.94 Moth Minor reached eight per week. Only two were used by the Civil Air Guard.

-

Flight 1940-09 / Flight

The modern Moth Minor.

-

Air Pictorial 1991-10 / Airshow Review

Регистрационный номер: G-AFNG [10] DH94 Moth Minor Coupe G-AFNG on finals at the Woburn grass runway.

-

Aeroplane Monthly 1983-04 / P.Jarrett - Grapevine

Регистрационный номер: G-AFNG [10] One of the lots in the Christie's auction: Tony Haig-Thomas's Moth Minor Coupe G-AFNG;

-

Aeroplane Monthly 1980-08 / De Havilland D.H.94 Moth Minor G-AFNG /Preservation Profile/

Регистрационный номер: G-AFNG [10] -

Aeroplane Monthly 1980-08 / De Havilland D.H.94 Moth Minor G-AFNG /Preservation Profile/

Регистрационный номер: G-AFNG [10] -

Air-Britain Archive 1985-02 / Impressment Review (21)

Регистрационный номер: G-AFNG [10] Moth Minor Coupe G-AFNG, probably taken in the early sixties with a background of Jackaroos possibly at Thruxton

Другие самолёты на фотографии: Thruxton Jackaroo - Великобритания - 1957

-

Air Pictorial 1992-03

Регистрационный номер: G-AFNG [10] One of the star items was this splendid D.H.94 Moth Minor Coupe G-AFNG which arrived from Boscombe Down.

-

Air Pictorial 1957-08 / Air Pictorial's photo-review

Регистрационный номер: G-AFNI One of the few remaining de Havilland D.H.94B Moth Minor Coupes is G-AFNI (c/ n. 94018) built in 1939. There are several 2-seat D.H.94A Moth Minors still flying, the difference being that the canopy is absent and the rear fuselage is shallower. Power: 90-h.p. D.H. Gipsy Minor inline. Maximum speed: 118 m.p.h.

-

Air-Britain Archive 1985-02

Регистрационный номер: G-AFOJ [5] This coupe Moth Minor G-AFOJ is seen here in the 1941 style markings that it wore on communications duties for the manufacturer.

-

Aeroplane Monthly 1991-12 / M.Oakey - Grapevine

Регистрационный номер: G-AFOJ [5] Intact but suffering from the effects of the British climate, having been stored in a barn since 1970, de Havilland Moth Minor G-AFOJ was acquired and recovered by the Mosquito Aircraft Museum in September 1991. One of only six surviving D.H.94s in the UK, 'OJ was obtained after many years of negotiation; the museum hopes to restore it to airworthiness, and Grapevine will be watching its progress.

-

Air-Britain Archive 1985-02 / Impressment Review (21)

Регистрационный номер: G-AFOJ [5] A post-war view of Moth Minor Coupe G-AFOJ

-

Aeroplane Monthly 1992-07 / Personal album. Civil

Регистрационный номер: G-AFOJ [5] Coupe D.H.94 Moth Minor G-AFOJ was owned by the Panshanger-based London Aeroplane Club during the Fifties. Today it may be seen at Salisbury Hall, the home of the Mosquito Aircraft Museum, where it is to be restored to airworthiness.

-

Air-Britain Archive 1985-03

Регистрационный номер: F-PFYR, F-BFYR, G-AFNF Formerly G-AFNF, c/n 94010, F-PFYR was fitted with a fully glazed coupe top of local design. It was cancelled during the sixties.

The Calais-based Moth Minor F-PFYR, which visited Lympne on 26/7/59 for the Bleriot celebrations, has a non-standard French-built coupe top. It was formerly F-BFYR, ex G-AFNF, c/n. 94010. -

Air-Britain Archive 1983-03 / 3 - New Zealand /Complete Civil Registers/ (10)

Регистрационный номер: ZK-AJX A fine shot of Moth Minor Coupe ZK-AJX in the colours of its last owners Central Hawkes Bay Aero Club of Waipukurua, taken at Mangere, Auckland by Ken Meehan.

-

Air-Britain Archive 1983-03 / 3 - New Zealand /Complete Civil Registers/ (10)

Регистрационный номер: ZK-AKL Moth Minor Coupe ZK-AKL in a decidedly unflattering colour scheme at the Rotorua Air Pageant in March 1963.

-

Flight 1939-03 / Flight Advertisements

The simple air brake, which has practically no effect on the fore-and-aft trim, is clearly shown in the picture which also emphasises the straightforward design of the chassis.

-

Flight 1939-06 / Flight

The perforated air-brake flap, which extends across the rear of the centre-section, has intermediate positions and can so be used to stretch or shorten the approach

-

Flight 1938-11 / Flight

The Gipsy Minor as installed in one of the D.H. Moth Minors now flying at Hatfield. This view shows the formation of the front of the air-scoop.

-

Flight 1939-07 / Flight

British power: De Havilland Gipsy Twelve (with the Moth Minor in the background)

-

Flight 1939-06 / Flight

How the cowling is hinged and held open. Less seriously, this photograph of a part of the production line might well be entitled : “Doing the Hatfield Walk.”

-

Flight 1940-04 / Flight

MOTH MINORS AT MASCOT. A glimpse inside the De Havilland works. The wings in the background seem to promise large production in Australia.

-

Flight 1939-06 / Flight

Some idea ot the production capacity of Hatfield is given by this photograph of the Minor shop.

-

Flight 1939-03 / Flight Advertisements

Behind the rear seat is a roomy compartment for luggage which will take two week-end suitcases as well as small articles.

-

Flight 1939-03 / Flight Advertisements

Control layout is simple and practical. There is a useful locker for maps and light luggage under the front instrument board.

-

Flight 1939-08 / Flight

The control and instrument layout of the Moth Minor as equipped for blind-flying training. Notice that in this case the pupil takes the rear seat while the instructor is in charge of all incidental controls.

-

Flight 1939-06 / Flight

The centre section and control mounting arrangements of the Moth Minor. The floor extension carrying the rudder controls is seen on the right. Luggage is normally carried in the starboard stub wing.

-

Flight 1939-06 / Flight

The Moth Minor’s structure and general layout is admirably shown in this cutaway drawing. The machine is normally flown from the front seat and it is seen here in standard dual-control form.

-

Flight 1939-06 / Flight

How the wing folding and securing mechanism operates. When the handle is pulled out and to the left (in this case), the two pins are released. Their position when in place can be finally checked through small holes cut in the leading edge.

-

Flight 1939-06 / Flight

Ingeniously simple is the cant lever undercarriage, the details of which can be seen in the cut-away drawing on the right. It has been designed so that wear shall be negligible, with plastic bearings for the sliding members.

-

Flight 1939-06 / Flight

D.H. Moth Minor (D.H. Gipsy Minor).

- Фотографии